- Home

- Machines ▾

- About Us

- Request a Quote

- Videos ▾

- News & Articles

- Customer Support

A client's business was experiencing significant growth so they came to ACASI Machinery to help them build a new bottling line to run their 2oz plastic bottles at 200-plus bottles a minute.

We built the line with an automatic bottle unscrambler (model Trusort-48 with a 35 cubic feet hopper), a 30-head pressure-overflow filler (model GI3300), an inline spindle capper with vertical wheel cap sorter (model Trucap-Vert), with cap elevator (model 370-000), and a 42" diameter accumulation table (model RA3200).

Even though the machines were all working to spec at the desired speeds, an issue arose. At the speed the line was operating we began having bottles knocked over prior to filling because the bottles were so light, which was causing backups and resulted in frequent line stoppages.

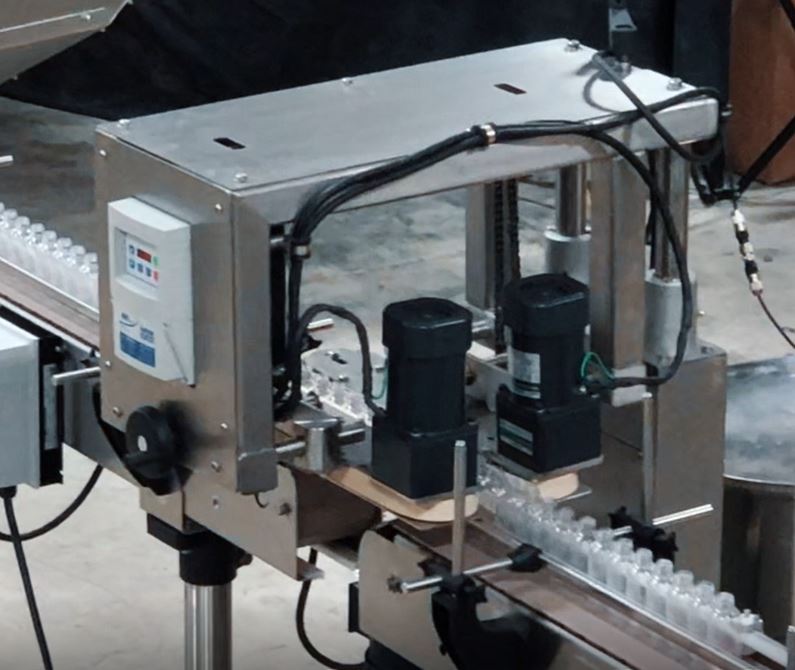

We added a gap transfer (model GT16) between the bottle unscrambler's conveyor and the filler's conveyor with backup sensors. This machine provided an elegant solution that virtually eliminated the issue by creating a seamless transfer between the conveyors.

If you're dealing with difficult to handle bottles that tend to fall over in your conveyor transfers, a gap transfer may be a good option to overcome this problem. Feel free to reach out to us to explore how we can help you have a more efficient bottling line. Click here for our request for quote form.

Sign up to get the latest on sales, new releases and more …

© 2024 Acasi

Raul Galofre

Author